Selecting a natural stone surface for a prestigious architectural or interior design project makes a powerful statement about enduring elegance and superior quality. Among all available materials, a marble slab stands as an unrivaled symbol of luxury, timelessness, and nature’s artistic mastery. However, choosing the perfect marble requires more than just appreciating its visual appeal—it demands a thorough understanding of the material’s chemical makeup, physical properties, and ongoing maintenance needs.

This Luxury Marble Countertop Selection Guide delivers a comprehensive examination of the essential factors that characterize natural marble, explores the distinctions between premium varieties, and provides crucial comparisons with contemporary engineered options.

Table of Contents

I. The Legacy of Luxury: Why Choose Natural Marble

The magnificence of marble extends far beyond its stunning appearance. As a metamorphic stone with a distinguished geological heritage, it represents an authentic investment in sophisticated interior design.

The Geological Identity of Marble: Metamorphism and Calcite Composition

Marble emerges from limestone through metamorphism—an intensive geological process where extreme heat and pressure transform the rock’s structure deep within Earth’s crust. This transformation causes the calcium carbonate (calcite) crystals within the limestone to recrystallize, creating the dense, interlocking structure and signature veining patterns that characterize marble.

The primary component of marble is calcite, a mineral that determines its physical attributes. Notably, calcite possesses a relatively low hardness rating compared to minerals such as quartz or feldspar. This fundamental composition means that while marble maintains structural integrity, it has distinct sensitivities requiring proper sealing and maintenance—a characteristic that sets it apart from surfaces primarily composed of silicon dioxide, like quartz or granite.

Establishing a Hierarchy: The Price of Purity and Rarity

Italy’s Carrara region quarries set the global benchmark for marble excellence. Within this premium category, value is largely determined by geological scarcity and background purity. The most coveted marble slabs showcase a pure white background, providing tangible evidence of minimal mineral impurities and thorough metamorphism.

The price hierarchy among natural marbles directly reflects these qualities of purity and scarcity. For example, the substantial price difference between widely available Carrara marble and the ultra-exclusive Statuario variety primarily stems from this geological pedigree. When specifying premium natural stone, higher price points are justified not just by subjective beauty but by concrete evidence of rarity and compositional purity, cementing the material’s position as a genuine luxury commodity.

II. The Grand Italian Trio: A Definitive Aesthetic and Functional Comparison

The three most prestigious Italian marble varieties—Carrara, Calacatta, and Statuario—embody distinct aesthetic profiles and corresponding levels of scarcity and cost. Understanding these distinctions is crucial for making an informed Luxury Marble Countertop Selection Guide decision.

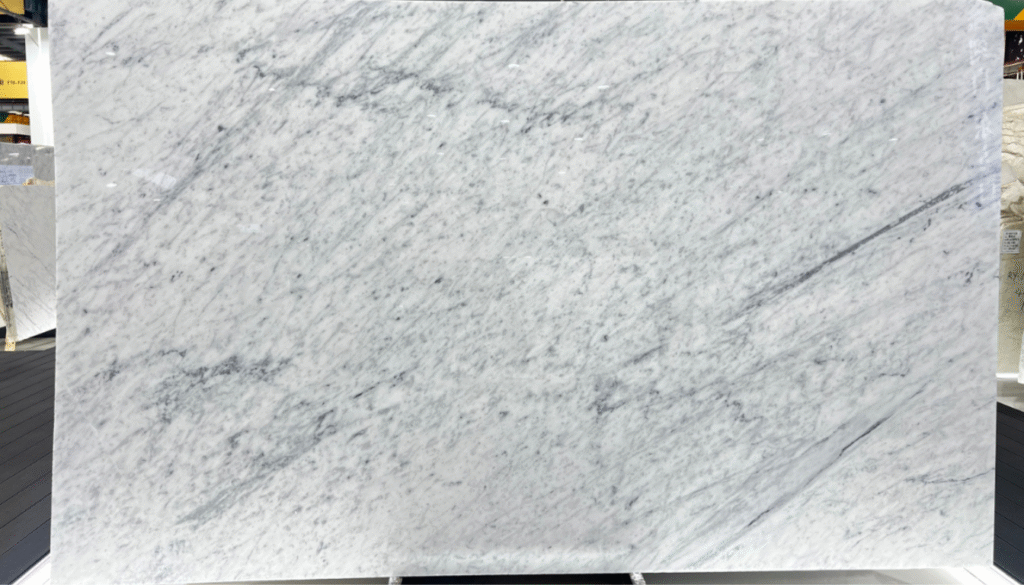

Carrara: The Foundation of Classical Design

Carrara marble slab showcases a distinctive light grey to white background adorned with subtle, feathery grey veining patterns that create an understated elegance. Its widespread availability in the marketplace makes it the most accessible option among the prestigious Italian marble varieties, offering excellent value without compromising on quality.

The consistent supply and cost-effectiveness of Carrara marble make it particularly well-suited for large-scale applications. It proves to be an ideal choice for extensive projects such as comprehensive flooring installations, expansive bathroom wall cladding, or extended commercial countertops, where achieving a timeless aesthetic and uniformity is essential without incurring the substantial costs associated with rarer marble varieties.

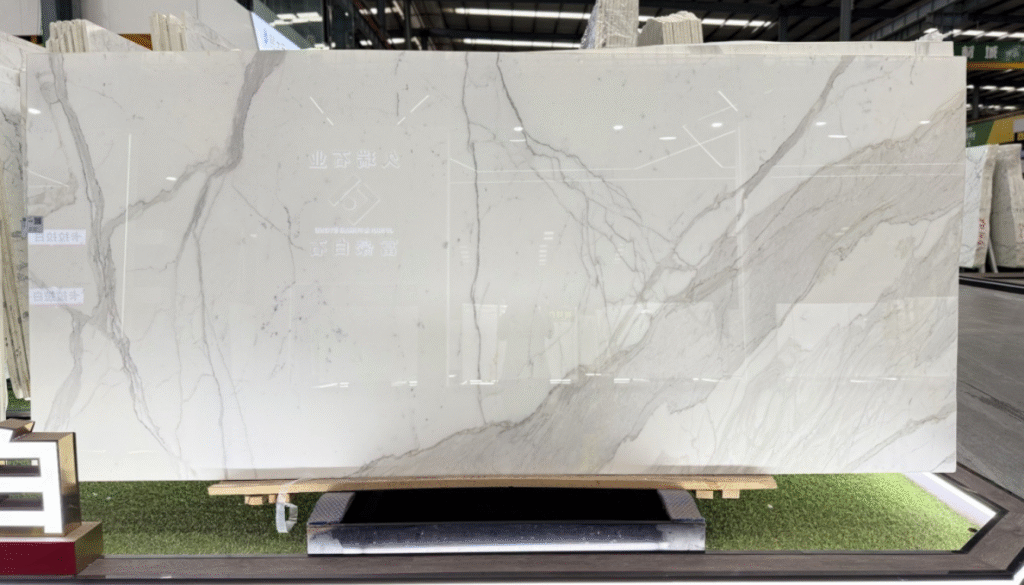

Calacatta: Veining, Color, and Unmistakable Presence

Calacatta marble distinguishes itself with an immaculate white background that creates a striking contrast to Carrara. Its veining patterns are characteristically bold and dramatic, featuring thick streaks that often incorporate a rich spectrum of colors from deep grey to warm gold and beige tones. The distinctive patterning and purer white foundation make Calacatta a rarer find, which naturally commands a higher market value than Carrara marble.

This exquisite marble variety excels in creating dramatic focal points within spaces. It’s perfectly suited for applications such as luxury kitchen countertops, sophisticated island waterfall edges, or prominent feature walls where its distinctive veining patterns can make a powerful visual impact. Calacatta marble delivers an unmistakable sense of opulence and grandeur, making it a preferred choice when seeking visual drama without the extreme rarity constraints of Statuario marble.

Statuario: The Apex of Whiteness and Dramatic Contrast

Statuario marble represents the pinnacle of Italian marble excellence. It features an exceptionally bright, pure white background that dramatically enhances its bold, thick grey veining patterns. As the rarest and most prestigious selection, Statuario commands premium pricing and is traditionally reserved for the most exclusive luxury interiors and fine sculptural artworks.

Statuario marble is best utilized in high-impact, limited-scale applications where budget considerations are secondary to achieving maximum visual drama. Ideal applications include sculptural elements, custom master bathroom vanities, or precisely bookmatched feature walls. While exceptionally dramatic Calacatta specimens may occasionally approach similar price points, Statuario’s consistently brilliant white foundation establishes it in the most exclusive luxury tier, symbolizing the ultimate in aesthetic refinement.

The functional differences are summarized in the following comparison:

Italian Marble Varieties: Comparison of Rarity, Aesthetics, and Use

| Attribute | Carrara | Calacatta | Statuario |

| Rarity & Price Tier | Common (Most Accessible) | Rare (High-End Luxury) | Extremely Rare (Highest Premium) |

| Background Color | Light Grey/White | Pristine White | Bright White |

| Veining Characteristics | Soft, Feathery, Delicate Grey | Bold, Dramatic, Colors Varying | Striking, Thick Grey, High Contrast |

| Ideal Application | Flooring, Volume Countertops, Bathrooms | Statement Kitchen Countertops, Feature Walls | Sculptural Elements, High-Impact Vanities |

III. Mastering Aesthetics: Color, Pattern, and Finish Selection

A thorough marble slab selection guide must explore beyond traditional Italian white varieties to encompass emerging color trends and the crucial decision of surface finishing, which carries significant practical implications.

The Spectrum of Sophistication: Utilizing Dark and Colorful Marbles

Modern design frequently gravitates toward the depth and richness that darker and colored marble varieties provide. Spanish selections like Nero Marquina present a dramatic black canvas with distinctive white veining, making them perfectly suited for contemporary or industrial spaces where luxury and strong contrast are desired.

Meanwhile, options such as Verde Alpi from Italy or Rainforest Green from India bring an unexpected, nature-inspired aesthetic. These green marble varieties excel at creating organic, natural atmospheres, particularly in bathroom settings or as distinctive design elements. When combined with metallic accents—such as Nero Marquina countertops paired with brass fixtures—these darker and vibrant marble slabs create an unmistakable sense of sophistication and adaptability.

The Art of Continuity: Bookmatching and Pattern Symmetry

In substantial installations like kitchen islands or statement walls, maintaining visual flow in the veining is crucial. Bookmatching, an advanced technique, achieves this symmetry by transforming the marble installation from mere surface coverage into a cohesive artistic statement.

This process involves cutting a large marble block into sequential slabs and polishing the previously adjacent sides. When these mirror-image pieces are placed side by side, they create a mesmerizing kaleidoscopic effect. Executing superior bookmatching requires sophisticated sourcing of premium-grade, consecutive slabs and demonstrates advanced fabrication expertise.

Finish Selection: Polished vs. Honed Performance Metrics

Choosing between polished and honed finishes represents perhaps the most important functional decision hidden within aesthetic preferences, especially for high-traffic areas like the kitchen and bath. Luxury Marble Countertops.

A Polished Finish is achieved through careful buffing with progressively finer abrasives, creating a high-shine, reflective surface. This finish enhances the marble’s color intensity and vibrancy, making spaces appear more expansive and brighter. However, the glossy surface tends to show light scratches more readily and, most importantly, the dull spots caused by acid etching. Maintaining its original brilliance often requires greater upkeep and potential periodic re-polishing.

In contrast, a Honed Finish is produced through the application of coarser abrasive materials, resulting in a smooth, matte surface that doesn’t reflect light. For marble slabs naturally prone to chemical etching (where acidic substances dissolve the calcium carbonate), industry experts strongly recommend this honed finish, particularly in areas with frequent use. The matte texture proves remarkably forgiving when it comes to everyday wear, effectively concealing minor scratches and etching marks, thus maintaining an elegant appearance with less visible signs of use. Additionally, honed marble surfaces provide enhanced traction, making them an ideal choice for potentially wet areas like bathroom flooring, where safety is paramount.

IV. Technical Due Diligence: Hardness, Porosity, and Structural Integrity

When discussing marble, it’s essential to address the material science fundamentals honestly, examining the physical properties that determine proper care requirements and manufacturing expertise.

Mohs Scale Reality: Understanding Marble’s Vulnerability

The fundamental characteristic of marble is its hardness rating. Primarily composed of calcite, marble typically registers between 3 and 4 on the Mohs scale of mineral hardness. This places it considerably lower than many alternative surfaces; for perspective, both granite and engineered quartz generally score between 6 and 7.

This lower Mohs rating has practical implications, making marble susceptible to surface abrasions. Every day, kitchen particles or dropped items, particularly sharp utensils, can easily cause scratches or surface wear. This reality necessitates mindful usage practices, such as consistently using cutting boards and trivets to preserve the surface’s finish over time.

Absorption Rates and the Risk of Staining

The metamorphic process that creates marble doesn’t eliminate all porosity. The stone maintains some degree of porosity, unlike fully sealed synthetic materials. Popular varieties such as Carrara marble typically show absorption rates ranging from 0.10% to 0.25%.

This inherent porosity means that liquids, including water, oils, and heavily pigmented substances, can penetrate the stone’s structure, potentially causing deep-set stains if not cleaned promptly. This characteristic makes regular sealing an absolute necessity to minimize long-term damage and staining risks.

The Importance of Slab Grading and Reinforcement

Natural stone slabs, especially delicate materials like marble and limestone, contain natural geological imperfections. Manufacturers classify slabs into grades (A, B, C, D) based on the presence of these defects, fissures, separation lines, and voids. Grade A marble contains minimal flaws, while Grade D marble exhibits numerous natural imperfections.

To ensure valuable, fragile slabs maintain structural integrity during transport, fabrication, and long-term use, reinforcement is a standard industry practice that should be understood as a professional quality assurance measure rather than a defect correction.

Epoxy Resins: Filling Fissures for Enhanced Durability

The application of epoxy resins represents a critical, time-tested standard in marble slab fabrication that has been refined over decades. Before shipping, manufacturers carefully dry the stone and apply a specialized penetrating epoxy resin coating. During an extended curing period, this resin penetrates deep into the marble’s natural fissures, pits, and microscopic cracks, significantly enhancing the slab’s structural integrity. This proven process substantially improves the stone’s overall strength, reduces its natural brittleness, and creates a more refined surface texture.

Beyond pure structural enhancement, epoxy treatments enable the marble to better withstand thermal fluctuations, making it more resilient in environments with varying temperatures. This proactive reinforcement technique allows fabricators to safely utilize a broader range of beautiful, high-value marbles with natural fissures in applications like Luxury Marble Countertops that would otherwise be impractical or risky.

Fiberglass Mesh Backing: Essential for Safe Fabrication and Handling

For particularly delicate or heavily veined marble slabs, an additional structural reinforcement layer of fiberglass mesh backing is applied to the reverse side. This critical support helps distribute stress evenly across the stone’s surface, significantly reducing the risk of tearing, fracturing, or breakage. This reinforcement proves especially vital during high-vibration cutting processes and throughout handling and transportation, ensuring the marble slab maintains its integrity throughout the entire fabrication workflow. Successfully implementing these sophisticated reinforcement techniques demonstrates advanced fabrication expertise and sourcing knowledge.

V. The Maintenance Imperative: Protecting Your Investment

While modern synthetic materials often claim to be maintenance-free, they frequently mask inherent thermal or structural limitations. Natural marble, while requiring regular maintenance, offers superior repairability—a crucial long-term advantage.

Sealing Protocols: Choosing the Right Impregnating Sealer

Due to marble’s natural porosity, consistent sealing is essential. A high-quality sealant serves as a vital barrier against moisture and acidic spills, simplifying cleaning routines and preventing mold or mildew growth in moisture-prone environments.

The most effective protection comes from water-based impregnating sealers. These specialized products penetrate the stone’s surface, blocking moisture absorption without creating a surface film that could chip or wear away. For kitchen and bathroom Luxury Marble Countertops, resealing frequency varies based on usage patterns and product quality, but applying new sealant every 6-12 months is typically recommended.

Identifying and Remedying Surface Damage

Proper marble maintenance requires understanding two distinct types of surface damage: staining and etching.

- Staining: Staining manifests when colored liquids like oils, wines, or coffee seep into the marble slab’s porous structure, resulting in darkened areas that contrast with the surrounding stone surface. Addressing these stains typically requires specialized chemical poultice treatments designed to gradually extract the absorbed contaminants from within the marble’s microscopic pores.

- Etching: Etching damage occurs through chemical reactions between acidic substances (such as citrus juices, vinegars, or harsh cleaning agents) and the marble’s calcium carbonate composition. This interaction dissolves the stone’s surface, creating dull, whitish patches that appear lighter than the surrounding marble. Essentially, etching represents a chemical burn that compromises the stone’s polished finish.

DIY Restoration: Techniques using Polishing Powder and Compounds

One of marble’s distinct advantages over modern synthetic materials lies in its exceptional repairability, offering superior long-term value despite occasional maintenance needs. Many minor etching issues, which present as dull spots or slight surface irregularities, can be effectively addressed by homeowners themselves.

The restoration process primarily involves applying specialized marble polishing compounds or powders specifically formulated for etch and watermark removal. These professional-grade polishing agents are designed to restore smoothness to affected areas. The process begins with thoroughly cleaning the marble surface using pH-neutral cleaners, followed by careful application and buffing of the polishing compound to restore the stone’s natural luster and surface consistency. However, for more severe etching damage or deep scratches, professional restoration services utilizing diamond abrasive techniques may be necessary to completely rehabilitate the surface through re-honing or re-polishing processes. This inherent ability to undergo both chemical and mechanical restoration represents a crucial durability feature unique to natural marble.

VI. Strategic Application: Suitability Across Residential Spaces

The optimal application of marble slab installations depends significantly on the homeowner’s willingness to maintain the stone and embrace its natural aging characteristics.

Marble in the Kitchen: Managing Acidic Hazards

Kitchens present the highest risk environment for marble installations due to frequent exposure to acidic ingredients like citrus fruits, tomatoes, and vinegar, along with potential oil spills. Successful kitchen marble applications rely heavily on diligent cleaning practices and maintaining robust sealant protection.

For surfaces intended for heavy daily food preparation, experts strongly recommend selecting a honed finish. This surface treatment proves more forgiving by naturally concealing the minor etches and scratches that inevitably result from regular kitchen activities. When incorporating marble in kitchen spaces, homeowners should embrace the concept of natural patina development over time – an aesthetic quality many consider a desirable indicator of the stone’s authenticity and lived history.

Future Trends: Backlit Marble Walls and Translucent Design

A key distinguishing factor when considering natural stone in Luxury Marble Countertop Selection Guide is its distinctive interaction with light. Unlike manufactured materials that remain opaque, certain white marble varieties (particularly high-grade Statuario and translucent stones like Onyx) possess an inherent translucent quality that sets them apart.

This unique characteristic is being innovatively utilized in contemporary design trends, specifically through the incorporation of backlit marble slab installations. By implementing sophisticated LED lighting systems, craftsmen can accentuate the stone’s intricate veining patterns and geological formations, transforming ordinary walls into captivating architectural elements. This refined approach showcases marble’s natural artistry in ways that engineered materials like quartz or sintered stone, which are primarily designed for consistency and opacity, simply cannot match.

VII. The Competitive Analysis: Marble vs. Modern Synthetics

To comprehensively evaluate marble’s value proposition, it’s crucial to examine its main competitors: engineered quartz and sintered stone. This comparison reveals that modern technical perfection often comes with significant compromises.

Engineered Quartz: The Trade-off between Consistency and Heat Limitation

Engineered quartz countertops combine 90% to 95% crushed natural quartz crystals with polymer resins and pigments. The main selling point of quartz lies in its aesthetic uniformity and near-zero porosity, achieved through the resin binder, eliminating sealing requirements. Leading manufacturers like Caesarstone and Silestone have developed sophisticated lines that effectively replicate natural marble veining.

However, quartz’s performance capabilities are fundamentally restricted by its polymer components. The epoxy resin binding agent starts deteriorating at relatively modest temperatures, showing significant mass reduction around 380°C (716°F). As a result, direct exposure to high temperatures—like placing hot cookware directly on the surface—can burn, discolor, or structurally compromise the resin, causing permanent, irreversible damage. This inherent heat sensitivity necessitates precautions that are typically unnecessary with pure mineral surfaces.

Sintered Stone (e.g., Dekton, Neolith): Extreme Technical Performance vs. Fabrication Fragility

Sintered stone, marketed under brands like Neolith and Dekton, represents an ultra-compact surface created through sintering technology. This process utilizes extreme heat and pressure to fuse natural minerals (quartz, feldspar, clay) into an exceptionally dense and hard surface. The result is a material boasting ultra-high Mohs hardness (typically 7-8+), minimal porosity, and superior resistance to UV exposure, chemicals, and high temperatures.

The Brittleness Paradox and Repairability Failure

Despite its remarkable surface hardness, sintered stone faces an inherent challenge – significant brittleness combined with poor fracture resistance. This creates an interesting material paradox: while the high density delivers exceptional performance characteristics, it simultaneously makes edges and corners particularly susceptible to chipping or breaking when subjected to concentrated vertical impacts. This vulnerability is so significant that fabricators typically avoid creating sharp 90-degree corners in sensitive areas. Major manufacturers like Cosentino have addressed this by incorporating reinforcing mesh (Protek) on the rear surface of their facade products to prevent falling debris in case of accidental breakage.

A critical limitation is that damage to sintered stone is virtually impossible to repair effectively. When edges chip, fractures occur, or the surface experiences subsurface scoring, restoring these areas to their original pristine condition becomes nearly impossible. While polymer-based fillers can somewhat mask the damage, the repairs remain visibly apparent, compromising the material’s aesthetic integrity and often requiring costly marble slab replacements.

The Total Cost of Ownership: Comparing Installation and Longevity

When examining material costs, mid-range quartz ($45–$120 per square foot) and sintered stone ($50–$150 per square foot) are comparable to mid-range natural marble. However, the total ownership costs show marked differences.

The ultra-high hardness of sintered stone necessitates specialized fabrication equipment, including water-cooled CNC machines and diamond tooling. This specialized requirement significantly increases labor complexity and installation costs, typically ranging from $80–$150 per square meter, notably higher than quartz installation at $60–$120 per square meter.

The most significant cost differential lies in long-term maintenance and repairability. While synthetic materials require minimal routine maintenance, their poor repairability means severe damage often requires complete replacement. In contrast, natural marble offers thermal stability and inherent repairability – surface imperfections can be polished away and the structure can be reinforced, ensuring the investment maintains its aesthetic value indefinitely.

Comparative Durability and Cost of Luxury Surfaces

| Factor | Natural Marble | Engineered Quartz | Sintered Stone |

| Mohs Hardness | 3–4 (Soft) | 6–7 (Hard) | 7–8+ (Ultra-Hard) |

| Porosity/Sealing | Porous; Requires Routine Sealing | Non-Porous; No Sealing Needed | Near Zero Absorption |

| Thermal Stability | High (Pure mineral structure) | Low (Resin decomposes) | Extremely High (Manufactured at >) |

| Chipping/Fracture Risk | Low to Moderate (Mitigated by reinforcement) | Low | High (Inherent Brittleness) |

| Repairability | High (Minor etches/scratches repairable with polishing compounds) | High (Cosmetically repairable with fillers) | Very Low (Severe damage often requires replacement) |

| Installation Difficulty | Moderate | Moderate | High (Requires specialized CNC tools) |

VIII. Conclusion: Making the Informed Choice and Final Consultation

The selection of a luxury marble slab ultimately comes down to a fundamental consideration: does the client value natural geological authenticity, unmatched aesthetic depth, and guaranteed repairability, or prefer zero-maintenance technical performance despite potential thermal and structural vulnerabilities?

Natural marble delivers timeless elegance, repairability, and distinctive artistry, though it requires consistent maintenance to prevent staining and etching. Engineered alternatives offer simplified care but risk irreversible damage from high temperatures (quartz) or impacts (sintered stone). The analysis reveals that reinforcing natural marble with epoxy resins and mesh backing isn’t a compromise but rather a critical quality assurance step ensuring this precious stone performs reliably.

Given the complexities of marble slab grading (A, B, C, D), reinforcement transparency, finish options (polished vs. honed), and the nuanced comparisons with synthetics, professional guidance isn’t just recommended—it’s crucial. Before making a significant investment, stakeholders should consult experienced fabricators, like the specialists at Zenova Stone, who provide expert recommendations